Energy infrastructure demands constant attention. As one example, energy companies face significant challenges in maintaining polymer insulators, critical components used to insulate and support high-voltage power lines. Kaitlyn Albertoli, CEO of Buzz Solutions, an advanced AI and predictive analytics software company, and Matthew Rogers, Supervisor of Electric Transmission Lines Operations at Dominion Energy, a U.S. energy company that provides electricity and natural gas across several states, embarked on a transformative journey to tackle the challenges of energy infrastructure resilience. By harnessing the power of drones and leveraging visual AI analytics, they may have set a new standard for energy asset management.

Shedding Light on the Problem

Polymer insulators, which consist of a fiberglass rod core with a polymer housing that protects it from the environment, help keep lights on and businesses humming. Conversely, their degradation diminishes power transmission and distribution.

The typical lifespan of polymer insulators should be between 20 to 30 years. However, environmental conditions and operations-related stresses, ranging from ultraviolet (UV) radiation, electrical and mechanical stress, chemical contamination to moisture and temperature fluctuations, can cause considerable degradation resulting in shorter life spans. This can ultimately lead to surface cracking, which causes reduced mechanical and electrical strength. All of this can impact the actual service lifespan of polymer insulators.

Without frequent, time-consuming and expensive inspections, it remains difficult for energy companies to accurately predict when insulators will need replacement. Traditionally, utilities have relied on less-than-optimal methods to assess insulator condition and determine if, or when, to replace them. These include visual inspections for surface damage, hydrophobicity (tendency to repel water or other polar molecules) measurements, infrared thermography, electrical tests like leakage current monitoring, corona (electrical discharge caused by the ionization of a fluid surrounding a high-voltage conductor) discharge testing and mechanical strength tests.

These approaches have significant limitations. Visual inspections of large numbers of insulators across transmission networks, for instance, can be both time-intensive and subjective. Surface-level inspections may miss internal degradation issues. Many electrical and mechanical tests require specialized equipment and specially trained personnel, which makes them costly to implement on a large scale. Some tests also necessitate taking power lines out of service, which disrupts electricity supply.

The limitations of traditional assessment methods require energy companies to carefully balance the costs of proactive replacements against the risks of unexpected in-service failures. These companies also face regulatory pressure to demonstrate proper asset management.

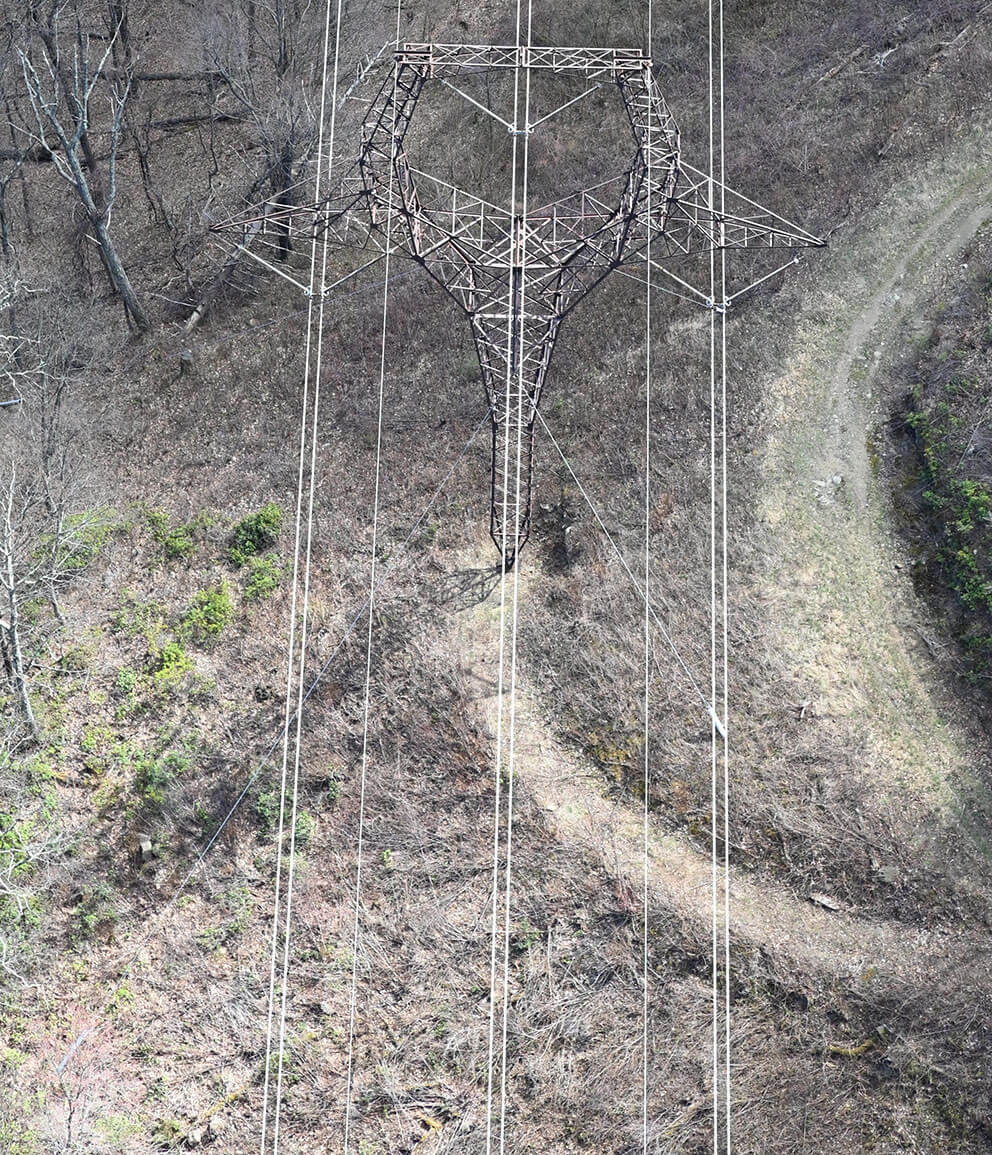

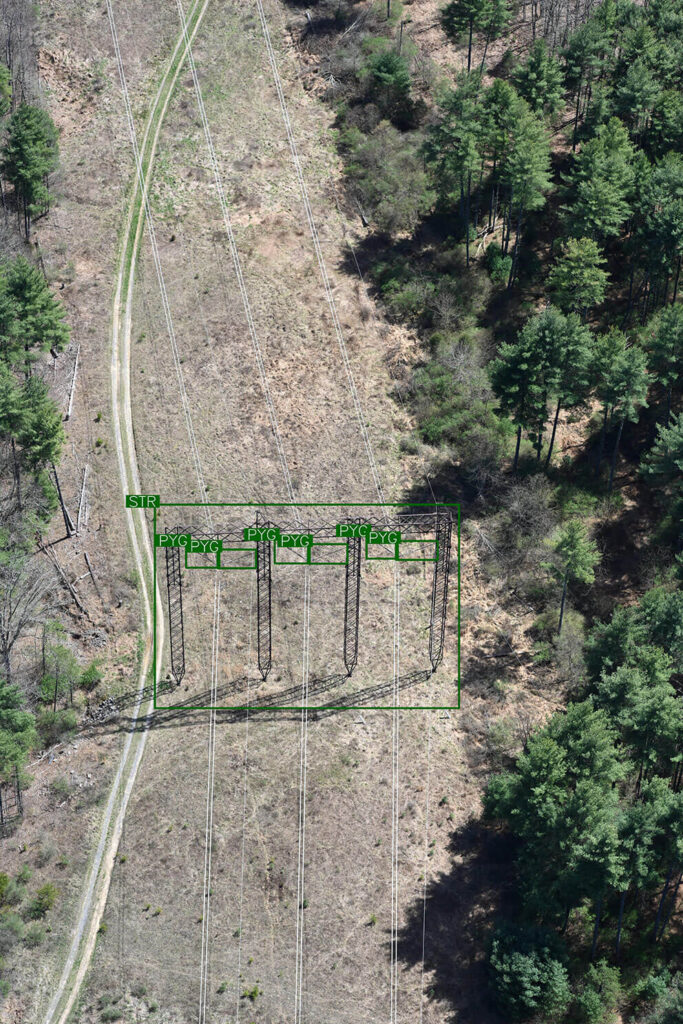

As a result, to better estimate insulator lifespans and optimize maintenance strategies, energy companies, including Dominion Energy, have started using drones to supplement data collection for infrastructure inspections. While this technology is cheaper, provides better quality and quantities of data, ironically, that same large amount of data has created its own set of problems.

Rogers from Dominion, outlined the challenges his company’s operations and maintenance (O&M) teams face. “The biggest problem with us on the O&M side,” he said, “is that we have a lot of data and not enough people to dedicate to the task of constantly analyzing it.”

Albertoli added, “You have data – now what?” “What do you do with that data to make sense of it and how do you turn it into actionable information?” she queried.

The answer she proposed to Rogers and his team: use Buzz Solutions’ visual AI intelligence platform, to make sense of all the data they collect from drones, helicopters and manned aircraft.

Humming Right Along

Dominion Energy’s polymer insulator program emerged as a prime candidate for AI-driven analysis. Together with Buzz Solutions, the company adopted a phased approach to prove the value of AI in their operations.

The initial phase began with a modest dataset of 500 oblique images captured by helicopter; data that Dominion had previously captured. Albertoli described the process. “We started with 43% accuracy,” she admitted. “That was not very good. Once we started using some of our engineers to help train the model and it was online, we were able to get up to 95% accuracy – even with lower-resolution images.” Buzz Solutions achieved this rapid improvement in inspection accuracy within just three weeks.

As the project progressed, the team faced the additional challenge of integrating this new tech into existing processes. Albertoli explained, “We spent a lot of time looking at the other platforms that Dominion Energy had been using on a day-to-day basis to make our AI a seamless part of its workflow.”

This required close collaboration with cybersecurity and IT teams, according to Rogers.

These integration efforts, in the end, created a more efficient data flow and “opened up the business case for using drones to inspect the Dominion system more quickly and inexpensively than traditional methods like helicopter, fixed-wing or foot patrols,” he said.

This return on investment (ROI) provided the confidence Rogers needed to scale up the project. The second phase involved an expansion to 4,300 images. Dominion Energy now has plans for full production across all 47,000 towers in its network.

The Future Shines Bright

The success of Dominion Energy’s polymer insulator program using advanced condition monitoring techniques with drones, coupled with AI-powered predictive models,

has shined a light on other potential applications within the company.

Rogers outlined some of these future use cases. “We’d like to perform this type of asset analysis on the identification of tower families. We only have a few different types of families within the Dominion infrastructure.”

The identification of tower families, or grouping similar towers into “families,” allows for more efficient management of large infrastructure networks. Companies can develop standardized maintenance and upgrade procedures for each family type. This enables a more systematic, data-driven approach for asset management which can potentially lead to improved reliability, safety and cost-effectiveness in energy transmission and distribution systems.

Rogers also mentioned plans to analyze steel structures, particularly in regions where soil acidity poses risks to infrastructure integrity. “We’d like to analyze this imagery to see where we have corrosion on steel structures,” he explained.

Finally, he noted the analysis of different foundation types as another area of interest. “We want to distinguish between direct embed structures and foundation structures,” Rogers explained. “This information could prove crucial for maintenance planning and infrastructure upgrades.”

Albertoli expressed optimism about the future of her company’s technology in aiding Dominion Energy, and others, to manage their assets more efficiently and proactively. “We will continue to refine our AI models and expand our clients’ capabilities to open up new asset management possibilities for utilities,” she said.

Rogers lauded the long-term benefits of the approach he and Albertoli have taken together. “By leveraging AI and drone technology, we did not just improve our operational efficiency,” he said. “We enhanced the reliability and resilience of our energy infrastructure. This ultimately benefits our customers and the communities we serve.”

The journey of Dominion Energy and Buzz Solutions serves as a compelling case study for other utilities that might seek to embrace innovative technologies in their grid modernization efforts. The integration of drones and AI analytics will undoubtedly play an increasingly critical role in shaping the future of energy infrastructure management.

Traditional energy inspections are:

- Time-consuming – Visual inspections of large numbers of insulators across transmission networks are extremely time-intensive.

- Expensive – Specialized equipment and trained personnel are required to conduct many of the electrical and mechanical tests.

- Disruptive – Some tests require taking lines out of service, disrupting power supply.

- Subjective – Visual assessments can be inconsistent between inspectors.

- Limited in scope – Surface-level inspections may miss top side degradation.