Achieving certification is a critical milestone for companies seeking to perform complex commercial autonomous and emerging aviation operations in the U.S. national airspace system (NAS). Certification is required so that these systems meet the stringent safety and operational standards to operate effectively and reliably in regulated environments. Charlton Evans, co-founder and CEO of End State Solutions, whose pioneering work in certification, has become a thought leader in this arena for the industry. In a recent Dawn of Autonomy podcast, Evans provided his perspective on certification, including lessons learned, pitfalls and best practices for business desiring to succeed in the competitive commercial uncrewed aircraft system (UAS) and advanced air mobility (AAM) markets.

From Marine Corps to Certification Expert

From his days flying jets in the Marine Corps to leading certification efforts for Boeing, Evans has built an impressive legacy of navigating regulatory challenges and ensuring safety standards.

Evans began his career as a Marine Corps aviator, piloting Harriers before transitioning into the burgeoning field of uncrewed aerial systems (UAS). Upon joining Boeing Insitu, he played a pivotal role in developing and certifying the versatile dual-use ScanEagle, a UAS capable of flight times exceeding 24 hours and operational altitudes up to 19,500 feet, for commercial operations.

Under Evans’ leadership at Insitu’s commercial division, the ScanEagle became the first UAS to perform FAA-approved beyond visual line of sight (BVLOS) flights in the NAS. This milestone demonstrated the aircraft’s reliability and safety standards. It also paved the way for even broader, and groundbreaking, operations in regulated airspace. A first-ever for the company and the entire UAS industry, Evans helped enable BNSF Railways to deploy the ScanEagle in New Mexico for inspections of rail infrastructure without the need for visual observers.

This critical work at Insitu laid the foundation for Evans’ expertise in FAA certification processes, particularly type and production certifications. This experience proved invaluable when he founded End State Solutions in 2018, a company dedicated to helping organizations achieve FAA approvals for airborne autonomous systems.

The Origin Story of End State Solutions

End State Solutions was born out of a clear need: to help companies navigate the intricate and often opaque world of FAA certification. With strong relationships forged with key players at the Federal Aviation Administration (FAA) during his time at Insitu, coupled with deep knowledge of regulatory frameworks, Evans saw an opportunity to guide businesses through the complexities of type certificates (TC), production certificates (PC) and operational certifications – and all the processes in between. The company’s mission is straightforward yet ambitious: transform prototypes into certified configurations ready for commercial use.

Evans emphasized that FAA certification is fundamentally about safety. “Every rule, whether it’s airworthiness rules or operational rules, exists to mitigate a hazard,” he said. “Airworthiness rules are there to mitigate ground risk through reliability, and operational rules are there to mitigate all the other risks created by flying in the airspace.” End State Solutions synthesizes actionable deliverables and artifacts that align with these FAA requirements so clients can move from development to revenue-generating service.

Type, Production, and Operational Certification 101

For complex operations, certification – often several certifications – will be required. “Every rule—whether airworthiness or operational—exists to mitigate a hazard,” Evans said.

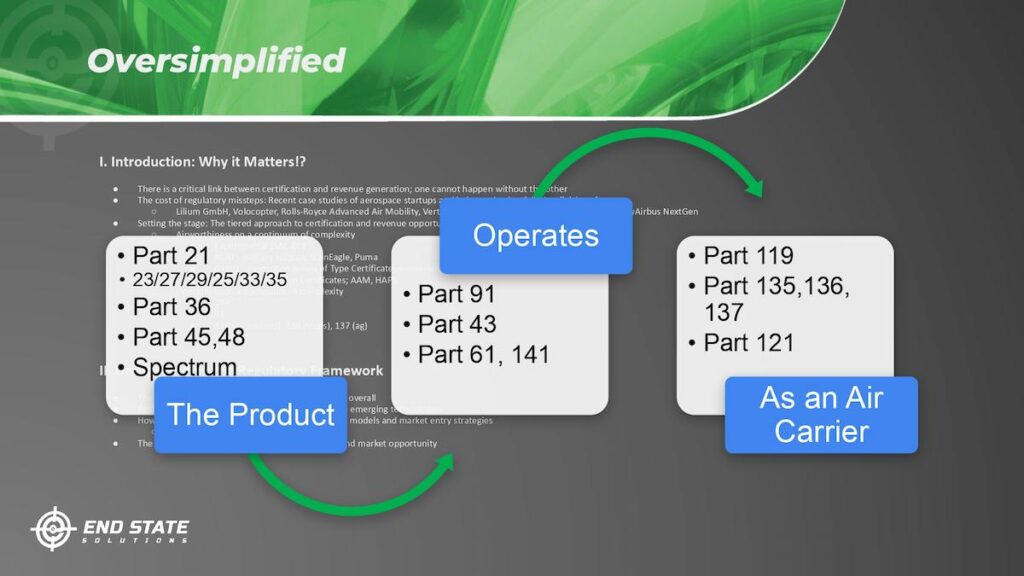

But certification is not a one-size-fits-all process. Understanding the types of certifications, at the highest level provides a basic educational starting point. Each mode—type certification, production certification, and operational certification—serves distinct purposes:

- Type Certification (TC): focuses on design approval. Engineers must demonstrate that every component meets FAA standards for functionality and reliability.

- Production Certification (PC): ensures that manufacturing processes consistently produce airworthy systems.

- Operational Certification: addresses how systems are deployed in real-world environments, like BVLOS “drone deliveries,” which fall under Part 135 carrier operations.

End State Solutions provides end-to-end support across all these facets, leveraging its team’s deep expertise—including former FAA policymakers—to streamline the path to approval.

Lessons Learned from the Trenches

Type Certification: Planning and Execution

Evans warned against underestimating the effort required early in the process. “Many companies fail to take into account the level of effort that has to go into a certification early on. If it’s planned for and intentionally approached, then it’s not such a big hurdle. But when companies overlook this, it can lead to significant delays and unanticipated costs,” he noted.

End State Solutions works side by side with a clients’ engineering team to assess every aspect of an aircraft’s design. The foundation of that effort, according to Evans, begins with defining a robust Concept of Operations (ConOps). This step is critical for clarifying the path forward. “The ConOps forces the company to understand its own product and how it will work in the environment it’s intended for. It defines requirements and clarifies your entire path,” Evans elaborated.

Production Certification: Achieving Consistency

“The production certificate certifies a quality system that illustrates the applicant understands every step of manufacturing and maintenance—and ensures it’s being accomplished as intended,” Evans explained. He elaborated, “The facility itself, along with its flow and processes, becomes part of what’s certified under the production certificate.” This holistic approach ensures not just compliance but also scalability, allowing companies to produce airworthy systems at scale without compromising on safety or reliability.

While production certification is generally more straightforward than type certification, it nevertheless requires meticulous planning to meet FAA standards. Evans highlighted that new technologies, such as advanced battery systems, can introduce complexities into manufacturing processes that require innovative solutions. “For example, when you’re dealing with novel manufacturing methods or integrating cutting-edge components, you need to ensure your quality system captures every nuance of that process,” he explained.

The importance of consistency in production cannot be overstated. End State Solutions’ team includes former FAA policymakers who specialize in auditing and building documentation that supports these systems. “Our role is to help companies develop robust quality management systems that meet FAA standards while ensuring their production processes are repeatable and reliable,” Evans noted. This includes conducting audits, creating production conformity plans and providing ongoing support to ensure every UAV rolling off the line meets stringent safety and quality requirements.

Operational Certification: Building a Strong Safety Case

End State Solutions’ work with Matternet exemplifies the challenges and triumphs of design assurance certification. Matternet made history by securing the first-ever type certificate for a drone delivery system under the FAA’s durability and reliability (D&R) framework. However, as Evans recounted, the process was far from straightforward. “It really didn’t pan out the way it was supposed to,” he admitted. “What should have been about a six-month process turned into over four years.” The FAA itself learned valuable lessons from Matternet’s case, which ultimately led to refinements in processes like the 44807 exemption pathway.

High Level Insights

Evans shared additional tips for businesses from his years assisting companies in the certification process. Here are his top three insights:

- Elevate Engineering Over Marketing: Companies often invest heavily in trade show booths while neglecting engineering efforts critical for certification success, in the early phase of their business models. “Reallocate resources toward engineering reduces program risks and increases success probabilities,” Evans advised.

- Calculate the Unit Economics: A strong assessment of market segments and unit economics is essential to ensure long-term viability after accounting for certification costs. In other words, have a solid use case lined up before designing an aircraft. Solve a need, don’t create a solution and then search for a problem to solve. And make sure the return on investment will be there for your business and any investors.

- There is No “Certification by Obvious”: Demonstrating compliance requires rigorous testing and documentation, not just assumptions about reliability. “Pushing back on demonstrating reliability only creates friction and delays,” Evans warned.

Opportunities to Excel…Togther

End State Solutions guides and supports businesses through every one of these processes. Evans explained that this involves much more than just submitting a request. It demands a compelling case backed by thorough risk assessments and operational safeguards. End States Solutions provides clients with value in these additional areas.

Waiver and Exemption Enablement: Getting to Yes

For operations like BVLOS, which lack standardized rules, companies must develop innovative solutions such as detect-and-avoid technologies or operational mitigations for midair collision risks. “There’s no script to follow for BVLOS beyond Part 107 right now,” Evans explained. “You’ve got to create a package that the FAA can digest, understand and approve…The FAA isn’t looking to say ‘no’—they’re looking for proof that a non-standard operation can be conducted safely.”

For example, the Section 44807 Exemption has emerged as a critical pathway for operators to conduct certain UAS operations, such as BVLOS ops, through exempting type certification. It offers a more flexible and expedited alternative for companies aiming to deploy emerging technologies. At its core, the 44807 process applies elements of the FAA’s Durability and Reliability (D&R) framework through an operational lens.

Evans described how this exemption bridges the gap between Part 107 operations and full type certification. “The 44807 process allows companies to declare that they’ve done the necessary testing and have the artifacts to back it up,” Evans explained. “It’s not about bypassing safety—it’s about demonstrating reliability in a way that’s more tailored to the operational environment.” This approach shifts some of the burden of proof onto the applicant while maintaining FAA oversight through extensive reviews, publication in the federal register and public comments on the ConOps.

Evan’s team excels at building all the various safety cases to secure FAA waivers and exemptions, especially for non-standard operations. By leveraging precedent research and detailed safety analyses to ensure waiver requests are well-supported arguments for approval. End State Solutions has been instrumental in several groundbreaking achievements:

- ScanEagle: Building on Evan’s history with Boeing Insitu and the Scan Eagle, End State Solutions enabled ConocoPhillips to deploy the ScanEagle commercially in the Arctic for BVLOS operations.

- Matternet: End State Solutions not only helped Matternet attain Part 135 operational approvals, it also helped to secure Matternet’s type certificate, a first-ever for UAS.

- Chevron: End State Solutions worked with Chevron and AATI using the 44807 pathway to unlock an exemption for BVLOS pipeline inspections across 4,500 square miles in California’s San Joaquin Valley. The operation utilized advanced Echodyne radar systems onboard AATI’s AI Ranger drones to ensure safe and reliable flights over critical infrastructure. “This was a massive airspace approval,” Evans said. “It shows what’s possible when you combine innovative technology with a strong safety case.”

By using a tailored approach to each client’s unique needs, End State Solutions has positioned itself as a leader in navigating the evolving regulatory landscape and ensuring companies set new benchmarks for operational excellence.

Flight Operations Support: Ensuring Success in Testing

Testing is integral to certification efforts, whether for type certificates or operational approvals. End State Solutions helps clients distill requirements and design test plans focused on critical performance metrics while ensuring full FAA compliance. “Testing demonstrates that the product works as advertised—it performs its intended function,” Evans said.

Evans emphasized that testing is not just about proving functionality—it’s about demonstrating reliability and safety under real-world conditions. “The goal is to show that the product works as advertised and performs its intended function without creating hazards,” he said. For companies pursuing complex operations like BVLOS or drone-in-a-box systems, flight operations support ensures that every aspect of testing is conducted rigorously and efficiently.

During flight operations testing, End State Solutions provides on-site support to oversee pre-flight checks, manage test programs, and liaise between clients and the FAA. End State Solutions provides comprehensive flight operations support, overseeing test programs and acting as a liaison between clients and the FAA.

“We’ve provided folks to go on-site and oversee testing programs, effectively managing the entire process while ensuring compliance,” Evans noted. This includes addressing issues in real-time, refining test plans and ensuring that all required documentation is accurate and complete for FAA submissions. He continued, “Flight operations support is about being there to ensure everything runs smoothly—from pre-flight checks to post-flight debriefs.” This hands-on approach minimizes setbacks, optimizes data integrity and ensures that testing aligns with FAA standards.

By embedding expertise directly into the testing environment, End State Solutions helps clients navigate challenges, reduce delays, and build trust with regulators.

Solutions to Reach Your Ideal End State

Evans’ insights into certification planning, production processes, operational approvals, testing and flight operations highlight why End State Solutions remains a trusted partner for companies navigating FAA regulations. By combining technical expertise with strategic foresight, they help businesses achieve certification efficiently by maintaining rigorous safety standards.

As Evans aptly put it: “You can’t get there from here without a certificate or approval.” For companies aiming to unlock commercial potential in autonomous systems, End State Solutions aims to help you get there…from here.